The working principle of infrared thermal imaging and an introduction to infrared detectors.

The corona virus can spread through droplets formed by coughing and breathing. Therefore, epidemic monitoring and prevention in public areas have become an important link in curbing the epidemic. During the Spring Festival travel season, airport hubs, high-speed rail stations, passenger terminals and other places hold a large passenger flow with crowded people everywhere, so the preliminary inspection of the crowd is of great significance. The symptoms of patients with the corona virus mainly reflect as fever, cough, dyspnea, and fatigue. Therefore, temperature screening has become one of the main methods of epidemic surveillance in public areas.

Judging from the current research situation, the body temperature screening equipment in public areas is mainly non-contact, including mobile screening systems, fixed screening systems, and handheld screening equipment. Compared with traditional contact temperature screening equipment (thermometers, etc.), non-contact equipment can rely on infrared intensity to perform online temperature monitoring of the target, achieve efficient and rapid screening of passing people, and greatly improve the screening efficiency.

Infrared is also known as infrared heat radiation with the wavelength ranging from 0.76 μm to 1000 μm between microwave and visible light. The amount of infrared energy is directly related to the temperature of the surface of the object and the characteristics of the material. The higher the temperature is, the greater the infrared energy will be.

▲Infrared spectrum distribution

The infrared screening instrument determines the temperature of the object through the amount of infrared radiation energy emitted by the object.

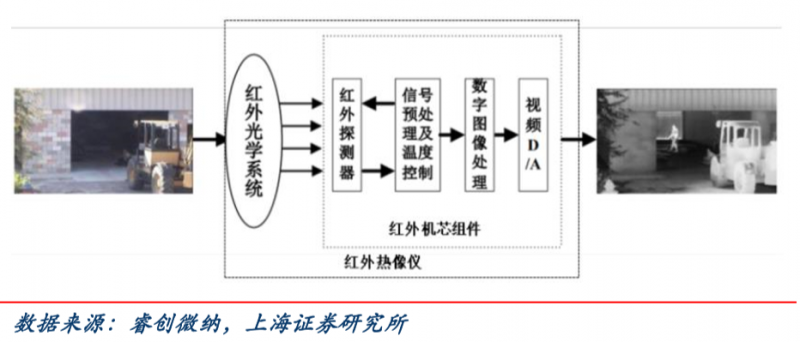

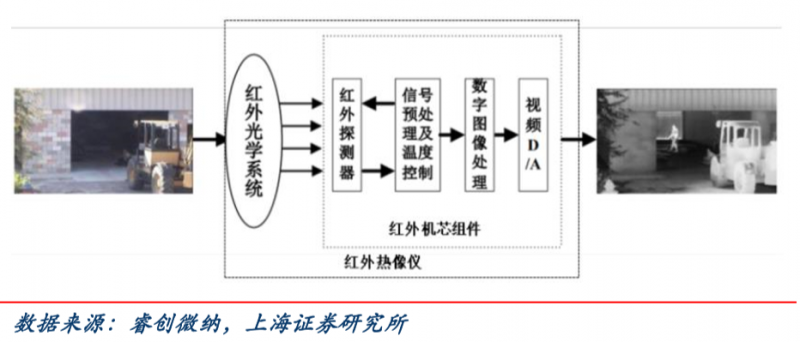

▲The working principle of infrared thermal imaging

To put it simply, infrared temperature screening is carried out in three steps:

The first step is to use infrared detectors sensitive to infrared radiation to convert infrared radiation into weak electrical signals, the size of which can reflect the strength of infrared radiation;

The second step is to use the follow-up circuit to amplify and process the weak electrical signal so as to clearly collect the temperature distribution of the target;

The third step is to process the above-mentioned amplified electrical signal through image processing software to obtain an electronic video signal. The TV display system displays the electronic video signal reflecting the target's infrared radiation distribution on the screen to obtain a visible image.

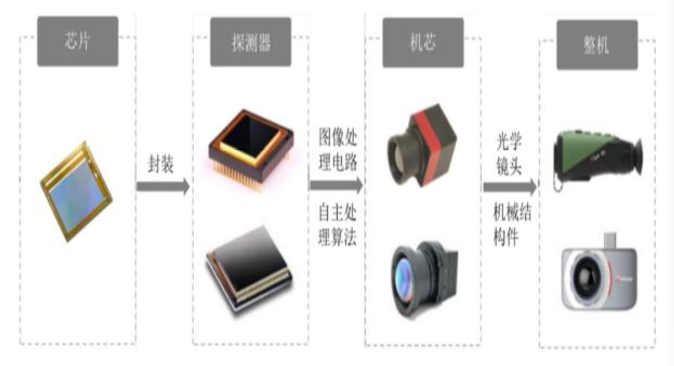

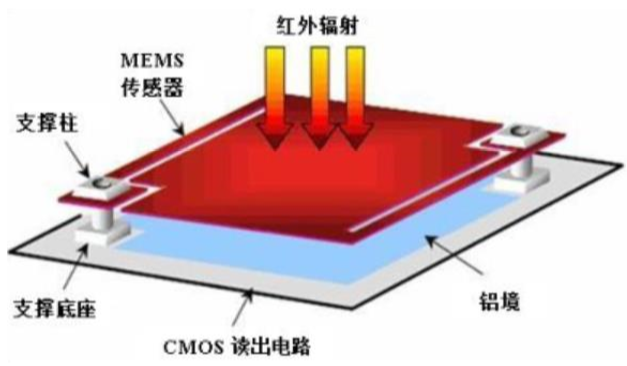

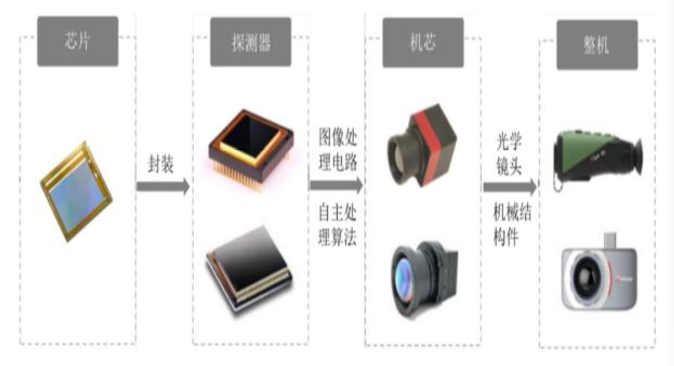

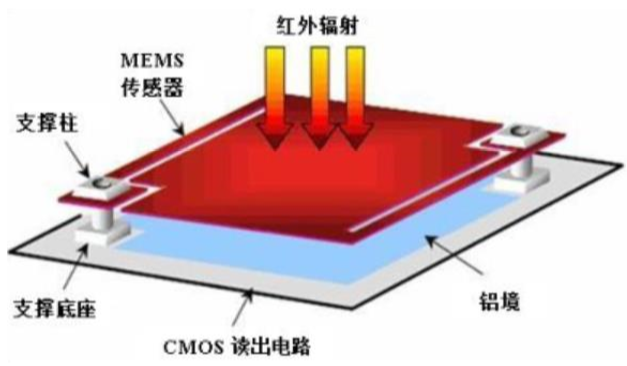

The infrared screening system can be divided into the chip, the detector, the movement and the whole machine. Infrared MEMS chip is the core component of infrared imaging system, which is at the upstream end of the entire infrared imaging industry chain. The infrared MEMS chip gathers the infrared light signals collected by the infrared optical system into the detector, and converts the infrared light signals into weak electrical signals for output through the IC and MEMS system.

▲Disassembly of infrared screening equipment

▲Introduction to infrared detector

The design, production and research and development of infrared detectors involve such fields as materials, integrated circuit design, refrigeration and packaging. The technology is so difficult that at present only a few countries can master the core technology of uncooled infrared detectors, which are the United States, France, Israel, and China.

The movement is composed of a detector and an image processing circuit with a common algorithm.The working principle of the movement is to process and digitize the weak electrical signal output by the detector, and process the digitized signal through an algorithm for image and temperature quantitative processing, and finally convert the temperature distribution map of the target object into a video image.The whole machine is a complete system composed of infrared optical system, movement, intelligent processing circuit, battery, casing, display screen, etc.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt ไทย

ไทย čeština

čeština dansk

dansk Svenska

Svenska